The Potential of 3D Printing in Revolutionizing Manufacturing Processes

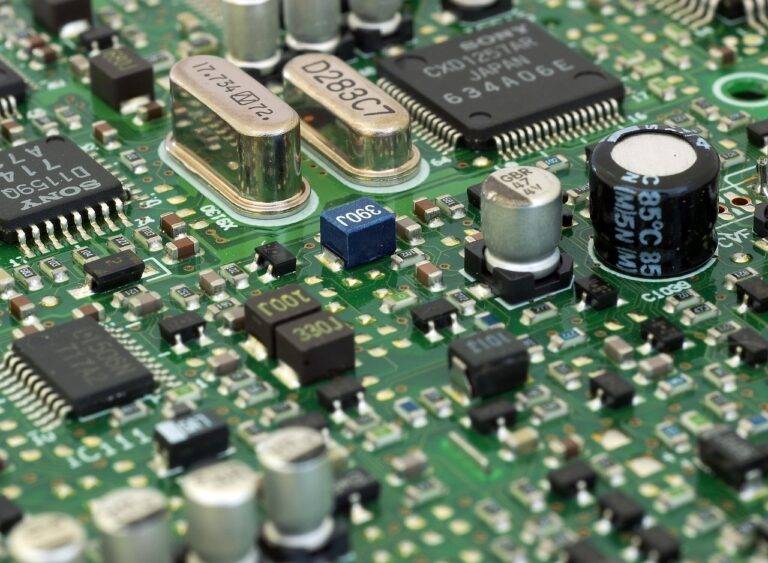

Manufacturing technology has undergone significant transformations over the years. From traditional manual labor to mechanized production lines, the evolution in this field has been instrumental in increasing efficiency and productivity. The introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems has revolutionized the way products are designed and produced, allowing for more precise and complex shapes to be manufactured with ease.

Moreover, the integration of automation and robotics in the manufacturing process has further streamlined operations and reduced human error. With the advent of Industry 4.0 technologies such as the Internet of Things (IoT) and artificial intelligence (AI), manufacturers are now able to connect and optimize their entire production processes for improved output and cost-effectiveness. These advancements not only demonstrate the evolution of manufacturing technology but also highlight the endless possibilities for innovation in the future.

• The introduction of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems has revolutionized product design and production

• Automation and robotics have streamlined operations and reduced human error in manufacturing processes

• Industry 4.0 technologies such as the Internet of Things (IoT) and artificial intelligence (AI) allow for connected and optimized production processes

• These advancements showcase the evolution of manufacturing technology

• They also indicate potential for further innovation in the future

Advantages of 3D Printing in Production

3D printing offers numerous advantages in the production process. One of the key benefits is the ability to create complex geometries that are otherwise difficult or impossible to achieve using traditional manufacturing techniques. This allows for the production of customized and intricate designs with precision and efficiency.

Moreover, 3D printing helps reduce material waste as it only uses the amount needed to create the object, unlike subtractive manufacturing processes where excess material is often discarded. This not only contributes to cost savings but also aligns with sustainable practices by minimizing environmental impact.

Applications of 3D Printing in Various Industries

The automotive industry is rapidly embracing 3D printing technology to enhance production processes. From prototyping to creating complex customized parts, manufacturers are leveraging the flexibility and speed of 3D printing to streamline their operations. Automotive companies are now able to reduce lead times, optimize designs, and cut costs by incorporating additive manufacturing into their production lines.

In the healthcare sector, 3D printing is revolutionizing the way medical devices, prosthetics, and even human tissues are created. Surgeons are utilizing 3D printed models for pre-surgical planning, leading to more successful outcomes and reduced surgical risks. Additionally, custom-fitted prosthetic limbs and implants are now being manufactured through 3D printing, improving comfort and functionality for patients in need.

What is the evolution of manufacturing technology?

The evolution of manufacturing technology has seen a shift towards additive manufacturing, also known as 3D printing. This technology allows for the creation of complex and customized objects layer by layer, as opposed to traditional subtractive methods.

What are the advantages of 3D printing in production?

3D printing offers numerous advantages in production, including reduced lead times, cost savings, increased design flexibility, and the ability to create complex geometries that are not possible with traditional manufacturing methods.

How is 3D printing being used in various industries?

3D printing is being used in a wide range of industries, including aerospace, automotive, healthcare, consumer goods, and more. In aerospace, for example, 3D printing is being used to create lightweight and durable parts for aircraft. In healthcare, 3D printing is being used to create custom implants and prosthetics for patients.

Can 3D printing be used for mass production?

While 3D printing is currently not as efficient as traditional manufacturing methods for mass production, advancements in technology are making it more feasible. Some industries are already using 3D printing for small-batch production or for creating custom, one-of-a-kind products.